Why is 5G so important to industrial manufacturing plants?

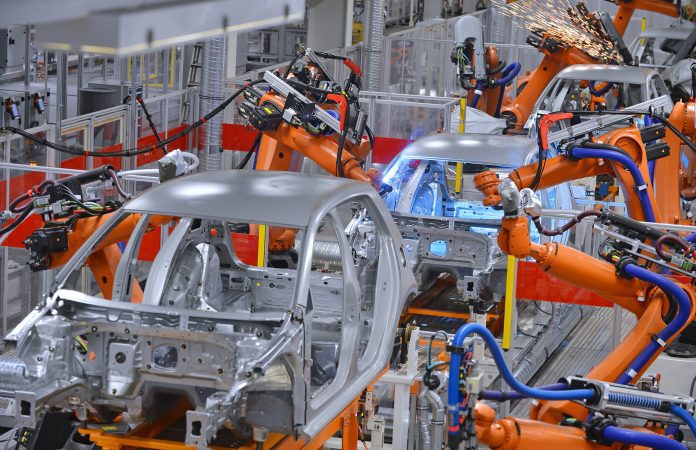

5G will provide manufacturing robots and other IoT devices in industrial plants and manufacturing facilities with greater security, reduced latency and dramatically increased connection speeds and reliability. The latency angle is perhaps the most significant benefit to the industrial facilities marketplace in that reducing the time it takes to send a data packet to less than one millisecond. For devices that need instant connectivity to react to a dynamic manufacturing environment, reduced latency can dramatically impact plant productivity.

Compared with existing connectivity options such as 4G LTE, Wi-Fi and Ethernet, 5G is expected to become a far better connectivity solution due to its ability to perform during network disruptions, add flexibility to equipment configurations, prevent cybersecurity hacks and control automated factory robots- a feature which is imperative as more plants deploy robots to complete tasks and streamline operational efficiencies.

Carmakers Audi, Volkswagon and BMW and large chemical, oil and gas plants and utility companies and majors shipping posts are planning to adopt 5G, according to analysts from MIT Technology Review.

Audi, which currently uses Wi-Fi as the primary wireless technology at its production facilities and connects its robots primarily via Ethernet has difficulty streaming data in real-time and moving robots, started testing 5G in late August of this year has plans to deploy the 5G in production facilities within the next two years.

With so many companies rapidly preparing to adopt private 5G cellular networks, its importance to the manufacturing and industrial facilities sector cannot be underestimated. So much so that the market for privatized 5G networks is expected to grow more than 30% to $356 billion within the next twelve months, according to US-based IoT research firm Harbor Research.

While the promise of 5G is undoubtedly attractive, there are significant deployment costs. First and foremost, access to the spectrum or the radio frequency that will carry the wireless signals is required. Today many manufacturers are turning to companies like Ericsson and telecommunications providers to sell their spectrum to them.

Once spectrum is secured, facility owners will need to acquire networking equipment and software and costs related to operating the network. While some companies may choose to use their in-house technology teams and assume carrier related responsibilities such as designing and maintaining the network, others will likely choose to outsource.